Jiangxi King Powder New Material Co., Ltd. Official

Search:Boron Nitride | Silica | Titanium Dioxide | Carbon Black Pre-Dispersion | Hydrophilic Pigment

Jiangxi King Powder New Material Co., Ltd. Official

Search:Boron Nitride | Silica | Titanium Dioxide | Carbon Black Pre-Dispersion | Hydrophilic Pigment

Product description:

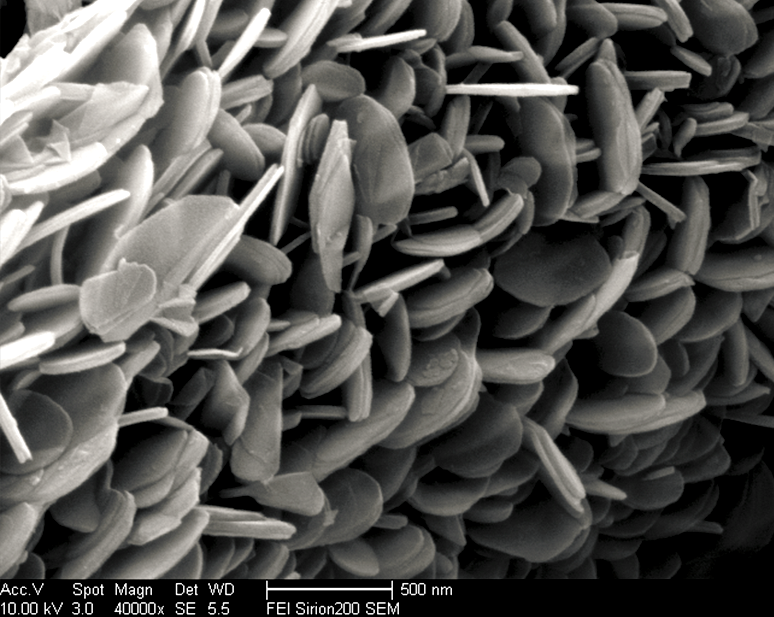

Boron nitride is not affected and infiltrated by most of molten metals, slag and dross, is not be wetted by most of molten metals, salts and fluxing agents, and thus has high tolerance to molten metal corrosion and light metal dross. BN is resistant to high temperature above 850℃, and has high temperature lubricity and corrosion resistance.

With special technique and formula, BNITIL NW-101 is a BN water-based slurry synthesized by high temperature resistant inorganic material. It can be used directly by spraying, brushing, impregnating, or diluting with water, suitable for a variety of permeable and non-permeable materials, such as graphite, metal and ceramics. Its fine parting plane and lubricity can provide excellent demolding effect even at high temperature, as well as increase corrosion resistance and service life of graphite and non-oxide refractory components and tools.

☆White dispersion liquid, aqueous solvent, a pure inorganic coating mainly consists of boron nitride.

☆High temperature resistance, the coating can withstand high temperature up to 850 ℃ after the dispersion is dry.

☆Strong adhesion, keeps strong adhesion with the base material and mold after dispersion coating is dry.

☆Superior surface anti bonding performance, not sticky with molten metal and spatter slag, not infiltrated with dispersion coating, difficult to accumulate and easy to demold.

☆Neutral pH value, anti-corrosion, chemical corrosion resistance, anti-oxidation, protects the base material and prolong the service life of mold.

☆The dispersion concentration is 15% and the viscosity is moderate. It can be directly sprayed, dip coated, brushed, or diluted in proportion. The coating surface can be used after fully drying, and the construction technique is simple.

☆The coating has good thermal conductivity and is a better choice for high-temperature operation, heat conduction and chill.

☆Good lubrication effect, enhances the smooth flow performance of molten liquid, improves surface smoothness, undistorts forming angle, good releasing effect.

|

Product Parameter |

|||

| Bnitril NW-101 | Hexagonal Boron Nitride | Coating Area (㎡/L) | 3-8 |

| Main Constituents of Water-Based Slurry | |||

| Appearance | White Emulsion | Viscosity(cps) | 300~800 |

| Solid Content % | ≥15 | pH | 7-10 |

| D50 Mean Particle Size (μm) | 3~12 | Packaging Specification | 50KG/Drum |

▲There will be soft precipitation when stored, which should be stirred evenly before use. It does not affect application.

▲It can be directly sprayed, dip coated, brushed, or diluted in proportion (not more than four times).

▲The temperature of molds or coated materials should be above 100 ℃, because low temperature will affect spreading evenness and bonding effect of coating.

▲It is enough to spray until fully covered, but no need to spray too thick.

▲The grease and dirt of molds should be cleaned in advance.

Pure Inorganic Raw Material

Temperature Resistance

After Dry and Forming Film

Application:

◆Hot forging of aluminum, titanium, copper and their alloys, lubricating release agent for hot stamping and hot extrusion

◆Mold release agent for glass hot bending and optical lens processing

◆Thermal conductive coatings

◆Anti-corrosion and anti-oxidation coating for titanium alloy forging, high temperature protective coating for launder and crucible

◆Anti-bonding isolation coating for trough, spoon, cup, ceramic sintering plate, etc