Jiangxi King Powder New Material Co., Ltd. Official

Search:Boron Nitride | Silica | Titanium Dioxide | Carbon Black Pre-Dispersion | Hydrophilic Pigment

Jiangxi King Powder New Material Co., Ltd. Official

Search:Boron Nitride | Silica | Titanium Dioxide | Carbon Black Pre-Dispersion | Hydrophilic Pigment

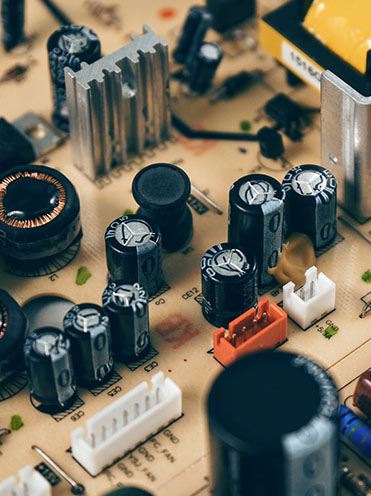

Electronics Industry with Insulation Thermally Filler

At present, the miniaturization of electronic products, has caused the wire spacing between large-scale integrated circuits gradually contracting in electronic circuit industry. It also brings higher requirements for fillers in dielectric constant, dielectric loss factor, surface resistance, breakdown voltage, thermal stress, thermal expansion coefficient, combustibility, peeling strength, thermal conductivity of the insulating medium, crystal radioactivity, and chemical stability.

For example, when encapsulating material is highly radioactive, source errors will occur during the operation of the integrated circuit, which will affect working reliability of very largescale integration (VLSI). The closer the thermal expansion coefficient of the encapsulating material is to that of the single-crystal silicon, the better the working thermal stability of the integrated circuit. Adding a large amount of encapsulating material can effectively solve the heat problem caused by 5G high frequency, but traditional inorganic powder fillers fail to meet the high requirements of future high-end electronic products.

After years research on the electronics industry and materials, King Powder has developed high-performance electronic fillers such as boron nitride, silicon micro-powder, wet processing talc, mica and so on. The requirements of fillers for electronic products include: low dielectric constant, strong resistance to voltage breakdown, low thermal stress, high thermal conductivity, good flame retardant effect, less metal and magnetic ions, superior mechanical strength and processability. Now, products from King Powder meet the above requirements very well.

For example, King Powder has spherical silicon micro-powder.

It has good fluidity, excellent machinability and can be stirred with the resin to form a uniform film;

It has high spheroidization rate and high filling rate in the resin (the highest can reach 90.5%), which perfectly improves the thermal conductivity of the resin;

Its thermal expansion coefficient is small, close to that of single-crystal silicon, contributing to good performance of the electronic components;

Its thermal stress is small, with concentrated stress and high strength of the plastic-coated products made of it;

It has small friction coefficient and less wear mold out, improving economic benefits; It is amorphous and chemically synthesized, containing less metal ions;

It has no radioactive α - ray pollution to the electronic circuit, and its uranium content is below 0.02ppb.

Besides, King Powder produces superior boron nitride.

It has lamellar structure, large specific surface area and strong heat conduction and dissipation effect;

It has small density, which are fit for prevalent light and fine products;

It is highly insulating with low dielectric constant and ionic content, which are more suitable for the electronics industry;

It can resist high temperature and oxidation, preventing material from aging to prolong product life;

It can resist corrosion, acid and alkali, well applied to internal-combustion engine and other fields where high temperature and corrosive exhaust resistance are required;

It has low thermal expansion coefficient, which keeps stable shape without deformation when heated;

It has proper hardness and superior machinability, without abrasion on machine;

It is coupled with special surface modifications of King Powder, which enhance the dispersibility and compatibility of boron nitride materials in high molecular polymer and other systems (dispersing evenly to improve thermal conductivity).

Application Industry:

Copper clad board, Electronic package, 5G base station, LED light, Wire and cable

Recommended Products:

Bnitril N (Boron Nitride powder), Bnitril NW (Boron Nitride paste), Spherical Boron Nitride

Silspher P (Spherical silica powder)

Talict (Talc)

Miapeal (Mica)